RAIL PROFESSIONAL - Very Light Rail

Published on: September, 2022

RAIL PROFESSIONAL AND THE VERY LIGHT RAIL STORY

Read the full article on page 98 - 100 via Rail Professional at https://issuu.com/railpro/docs/rp_uk_september_2022_issuu_v2?fr=sMWM5YTUzMzY3OD

Article content below:

5 THINGS YOU NEED TO KNOW ABOUT THE DESIGNERS AND MANUFACTURERS BEHIND 21st CENTURY'S MOST IMPRESSIVE VERY LIGHT RAIL (VLR)

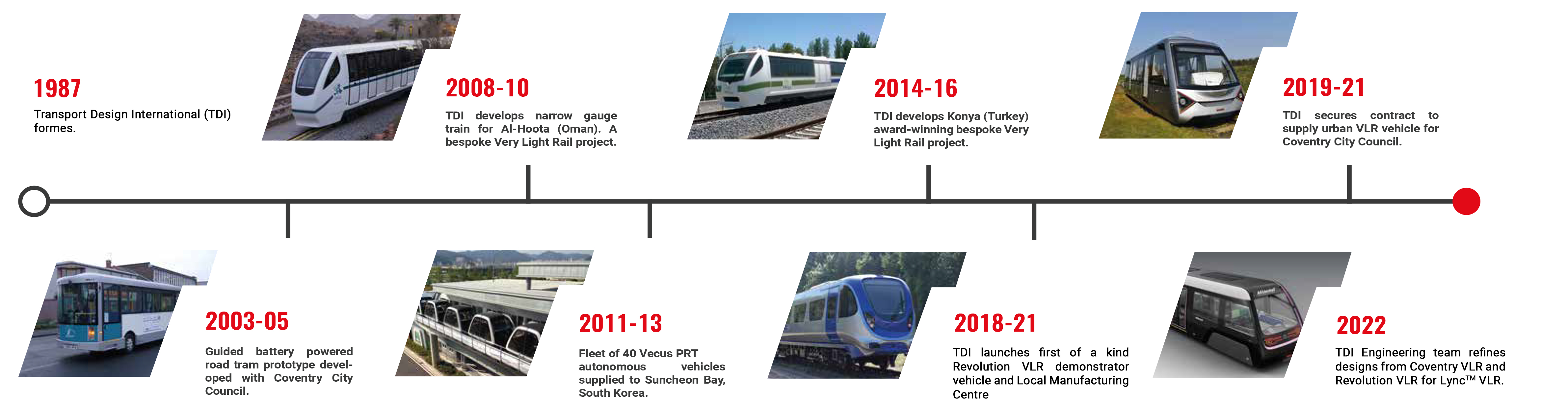

Transport Design International (TDI) is the company spearheading Very Light Rail (VLR). The story of VLR began over 35 years ago and has evolved from the design and development of Vectus Personal Rapid Transit vehicle, to the highly acclaimed Revolution VLR and Urban VLR vehicles it manufacture today. TDI specialises in the design and innovation of cutting-edge vehicles with the very latest technology in light weighting (VLR) and EV drive systems.

1. Very Light Rail operates in both Urban and Rural, branch line environments.

At a glance, few people realise that Revolution Very Light Rail (RVLR) and the Coventry Very Light Rail (CVLR) have developed from the same product, TDI's Vectus vehicle.

The Revolution VLR train was adapted to serve existing branch lines and rural applications. With platform height functionality it is suitable for ‘last mile’ transport solutions connecting rural and suburban communities to urban hubs. In contrast, the Coventry VLR tram, was developed to meet the needs of Coventry’s urban commuter environment, specific to the city requirements of Coventry. The compact size gives ability to negotiated tight corners with the full functionality of a conventional tram. For both vehicles, their much lighter weight means infrastructure demands and costs are greatly reduced.

TDI have had considerable international interest in their VLR products and are currently working on their Third generation urban vehicle Lync™ VLR, an exciting new addition for the future.

“Lync’s thoroughbred credentials emanate from 35 years of TDI innovation in the field of Very Light Rail. This next generation vehicle is designed for a clean Carbon Zero future that will meet the high expectations of today’s passengers, by providing a safe environment that allows passengers to carry on with their communications in this new digital world.” Shaun O’Brien, Commercial Director for TDI.

Lync VLR, has a spacious and innovative design both in the interior and exterior configuration of the vehicle and can be adapted to both rail or road applications.

2. Very Light Rail has been 35 years in the making

“This is proof of the great innovation that can and will take place when boundaries are pushed, radical ideas are encouraged and adequately supported, and strong collaborations across the transport sector are established and fostered.” Luisa Moisio, RSSB

3. Midlands is the birthplace of VLR

Transport Design International, is a Midlands based company operating out of their head office in Stratford-Upon-Avon. Both, Coventry VLR and Revolution VLR vehicles were built by TDI at their Local Manufacturing Centre (LMC) at Long Marston Rail Innovation Centre in Warwickshire.

TDI recently won the prestigious Made in Midlands Award for their work with Revolution VLR. “We are delighted that Transport Design International has won this prestigious award. It recognises the ground-breaking achievement in bringing the innovative Revolution Very Light Rail vehicle from concept to reality. It has been a great team effort and we look forward to working together in the next phase of the programme to build on strong market interest by securing production orders.” Tim Burleigh, Eversholt Rail.

The award reflects a wider recognition for TDI in the design, engineering and manufacture of Very Light Rail in the Midlands and highlights the increasing economic importance of this technology within the rail sector.

TDI were also Highly Commended at Modern Railway’s Rail Innovation Awards in July 2022 for their work on environmental and sustainability initiatives with RVLR. Their use of local supply chain in the manufacturing process invigorated the regions levelling-up programme. Very light Rail transport solutions, provide an alternative economic model for developing our rail network and supporting modal shift from road to rail.

4. VLR supports local supply chains

TDI set up its first manufacturing site in the Midlands, supporting jobs and commerce in the local community and accelerating SME growth. This model of using Local Manufacturing Centres is an integral part of the build process for TDI. This allows TDI to deploy their ‘create local – deliver local’ philosophy in regional hubs where the local economy can benefit from their own VLR rail investment. The supply chain for Revolution VLR and Coventry VLR used up to 70% of national and local suppliers, within a 50 km radius of TDI’s Local Manufacturing Centre in the Midlands.

Integration and resource upskilling, including increased apprenticeships with local colleges/universities is part and parcel of TDI Design and Engineering. Thus, creating an economically sustainable environment for material resourcing, and providing jobs and security in the local community.

Very Light Rail is quicker to deploy than heavy rail. The Revolution VLR Demonstrator vehicle was moved to a purpose-built facility at Ironbridge in September 2021 where it is undergoing further testing. The Ironbridge site supports stakeholder events and showcases the vehicle in a line-reopening context, with over 300 stakeholder visits to date. Ironbridge, demonstrates the possible speed of deployment for a Revolution VLR based solution. The first track inspection took place in February 2021, subsequent track remedial work and the build of a new platform and station buildings were completed in 6 months, with the entire site launched in September 2021.

5. VLR has Zero-Carbon Emissions

Sustainability in its widest sense has been at the heart of the VLR programme for TDI. To create a compelling proposition that will encourage modal shift to rail, any Very Light Rail whole-system solution must be both environmentally and economically sustainable. The need for economic sustainability has been highlighted in the Williams-Shapps Plan for Rail and the Department for Transport’s recent Transport Decarbonisation Plan, and there is a clear Government commitment to drive decarbonisation and transport improvements at a national and local level.

TDI has made quantifiable carbon reductions a fundamental part of the design and manufacture of their VLR vehicles, ensuring RVLR has zero-carbon emissions when operating at speeds below 20mph. Delivering substantial noise reduction in built up areas is also an important factor to consider and RVLR runs at less than 80 decibels when operating in pure EV mode.

Read the Full Article here: Rail Professional and the Very Light Rail Story

RELATED POSTS

The latest news from TDI

An overview of Q2 The world of Lightweight Thinking at TDI is growing. Our focus for Q1 and Q2 has been on establishing product launch foundations and conducting core product engineering work. We are

INTERPARK AND THE TDI STORY

INTERPARK Published on: July/August, 2023 Your Content Goes Here Read the full article on page 36 - 37 via InterPark at https://edition.pagesuite-professional.co.uk/html5/reader/production/default.aspx?pubname=&edid=4a43b1b6-9903-4d32-afdc-60f5e67f1d19

REVOLUTION VLR WINS INNOVATION AWARD AT RIA RISE AWARDS 2023

RAILWAY INDUSTRY ASSOCIATION (RIA Rise Awards 2023) Published on: June 30th, 2023 Your Content Goes Here Read Railway Industry Association's Press Release on Revolution VLR